Characterisation of raw materials (clays, kaolins, feldspars, quartzes, etc.) and formulation of optimised compositions for ceramic processes and products (building products, porcelain, etc.) and selection of additives (binders, deflocculants, barium carbonate, etc.).

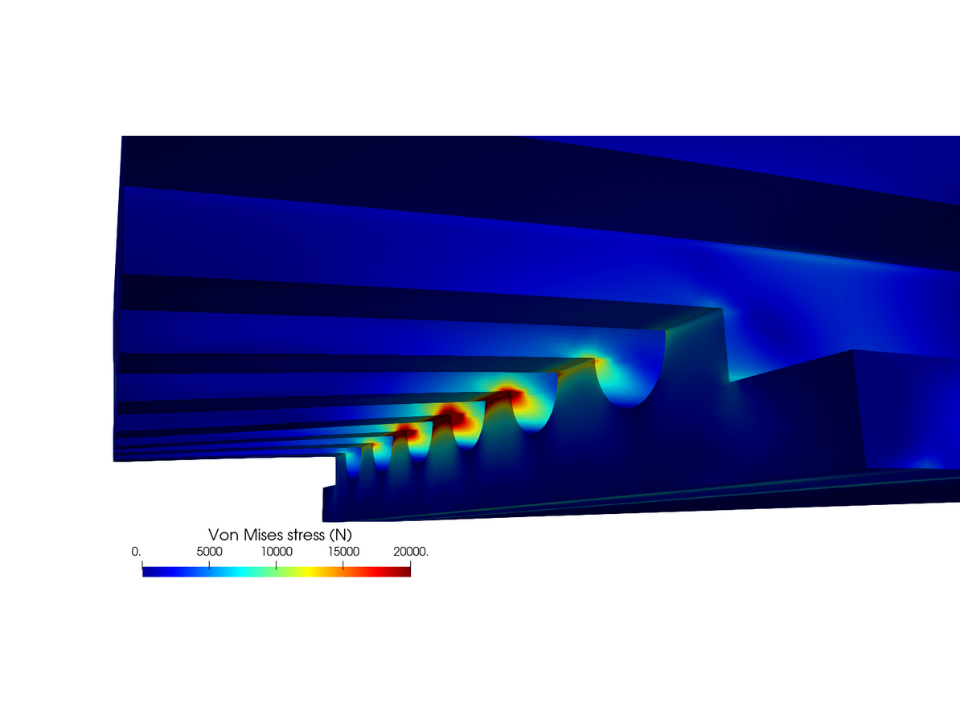

Prediction of new materials and product performance before the development stage, applicable to heat and mass transfer (drying, firing), to granular media, to mechanical performance in new applications, to design of complex geometries, etc.

Investigación y desarrollo de tintas inkjet adaptadas a los procesos digitales para aplicaciones multifuncionales y multisustratos. Determinación de las propiedades requeridas para una adecuada imprimibilidad, control de calidad y desarrollo del workflow óptimo. Síntesis de nuevos materiales que aporten nuevas propiedades. Desarrollo y gestión del color y gamut colorimétrico en procesos digitales.

Primer laboratorio español acreditado por ENAC para ensayos de eliminación de óxidos de nitrógeno según la Norma ISO 22197 -1 y UNE 127197-1. Ya disponible el ensayo de eliminación de formaldehído según la Norma ISO 22197-4.

Ambos ensayos caracterizan el rendimiento de purificación de aire de materiales fotocatalíticos aplicados en diferentes sustratos (hormigones, pavimentos, cementos, pinturas, cerámicas, etc.), y otras tipologías como asfaltos.

Desarrollo de recubrimientos con prestaciones optimizadas y características específicas (superficies antideslizantes, materiales biocidas, barreras térmicas, superficies biocompatibles, superficies resistentes al desgaste y a las manchas, etc), adaptados a todo tipo de materiales y superficies.

Study of problems appearing in ceramic products during installation, (visits for on-site checks, tests for determining causes, proposals for avoiding repetition of the problem, and issue of expert reports).

Desarrollo de nuevos materiales para construcción obtenidos a partir de materias primas y residuos silicoaluminosos. Se obtienen por activación alcalina a temperatura ambiente, minimizando los costes energéticos de proceso.

Development of new ceramic products with special properties such as high, controlled porosity (membranes); lightweight products (ceramic foams), and thermo-insulating products.