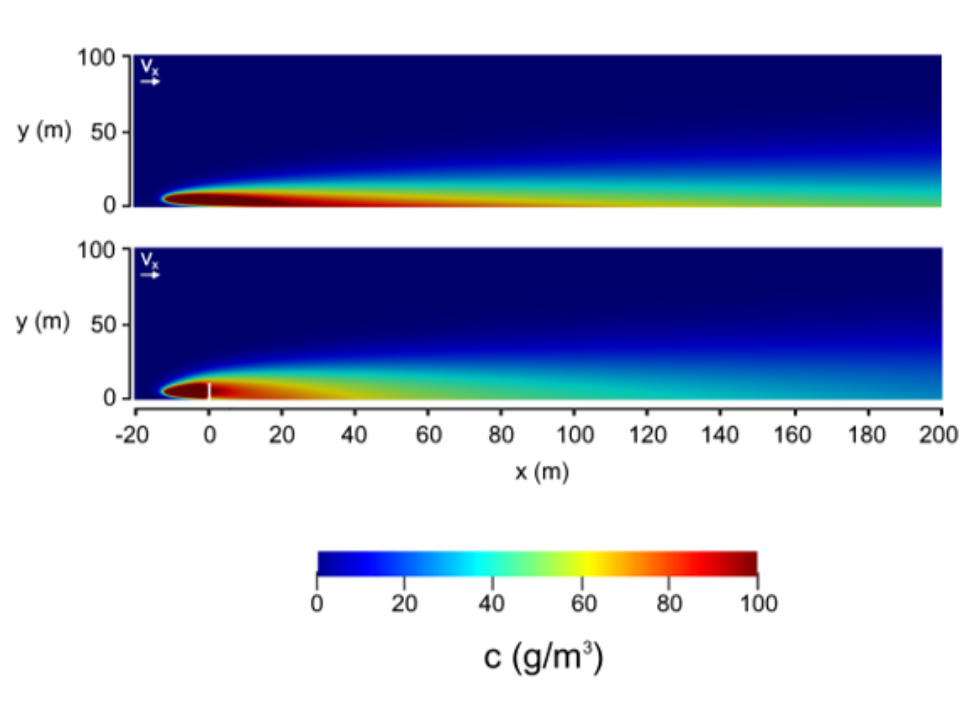

Characterisation of diffuse and channelled emissions (particulate matter (PTS, PM10, PM2, 5 and nanoparticles), acid pollutants, combustion gases, VOCs, etc.), identification of tracers, selection of BATs, development of BAT techniques for emerging pollutants, application of complex atmospheric and pollutant diffusion models, emission inventories and advice for the development of air quality improvement plans.

Realización de auditorías energéticas en procesos industriales para la identificación de oportunidades de reducción del consumo de energía: optimización de variables de proceso, aprovechamiento de calores residuales, búsqueda de las mejores tecnologías de recuperación de calor. Análisis termográfico de las instalaciones. Reducción de emisiones de CO2. Simulación de la transferencia térmica. Formación a medida.

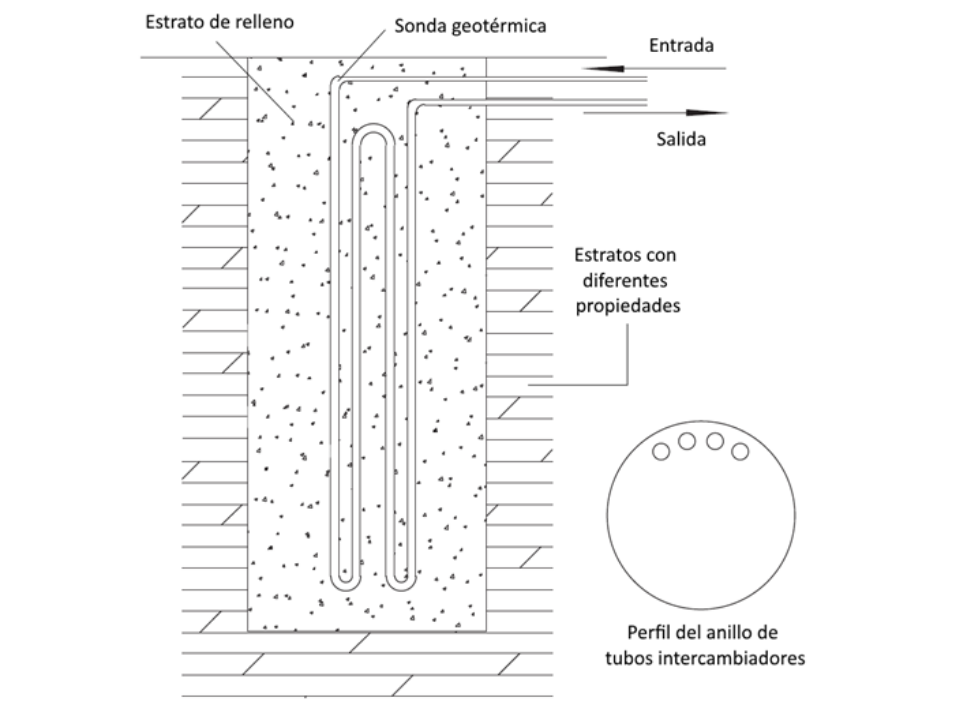

Realización de ensayos, simulación y análisis de la caracterización del terreno para el diseño de instalaciones geotérmicas de muy baja temperatura:

– Selection of the type of facility (open–closed–horizontal–vertical)

– Determination of ground thermal properties.

–Analysis of building energy consumption.

Recycling of solid urban and industrial waste, by treatment and conditioning for use as raw materials in ceramic products. Design of products and processes for recycling large amounts of waste.

Drawing up Water Saving Plans and improved wastewater management in the production process: Traditional treatments and application of organic membrane techniques in removing emerging pollutants, boron, organic compounds…

In-depth studies on occupational exposure to chemical and physical agents. For example, particulate matter (PM10, PM2.5, nanoparticles, etc.), respirable crystalline silica, handling of metallic mercury, materials containing natural radioisotopes and/or heavy metals.

Adaptation of raw materials and products to progress in chemical substances legislation. Drawing up safety data sheets and labelling according to REACH and CLP Regulations.

Identificación y diseño de metodologías/herramientas estratégicas a medida para mejorar y comunicar la sostenibilidad ambiental de productos y/o proceso (ecodiseño, análisis de ciclo de vida, ecoetiquetados (DAPs,..).

Environmental analysis of the company situation regarding air pollution and drawing up a plan for improvements aimed at reducing pollutant emissions.