- Constructed a wall of bricks made from waste and avoiding the firing stage in the framework of the LIFE HYPOBRICK project, financed by the European Commission through the LIFE Programme (ref. LIFE18 CCM/ES/001114).

- La empresa Ladrillos Mora, miembro del proyecto coordinado por el Instituto de Tecnología Cerámica (ITC-AICE), utiliza alrededor de 9.000 ladrillos sostenibles en esta construcción en Illescas (Toledo), con similares propiedades a los tradicionales y ahorrando un 80% de emisiones de CO2 a la atmósfera.

29/12/2022.- The LIFE HYPOBRICK project, financed by the European Commission through the LIFE Programme (ref. LIFE18 CCM/ES/001114) has almost come to its end with the construction of a wall of sustainable bricks in line with the circular economy and climate action, as they have been obtained from waste and applying technologies that avoid the high energy consumption of industries such as the brick manufacturing, and also saving harmful emissions.

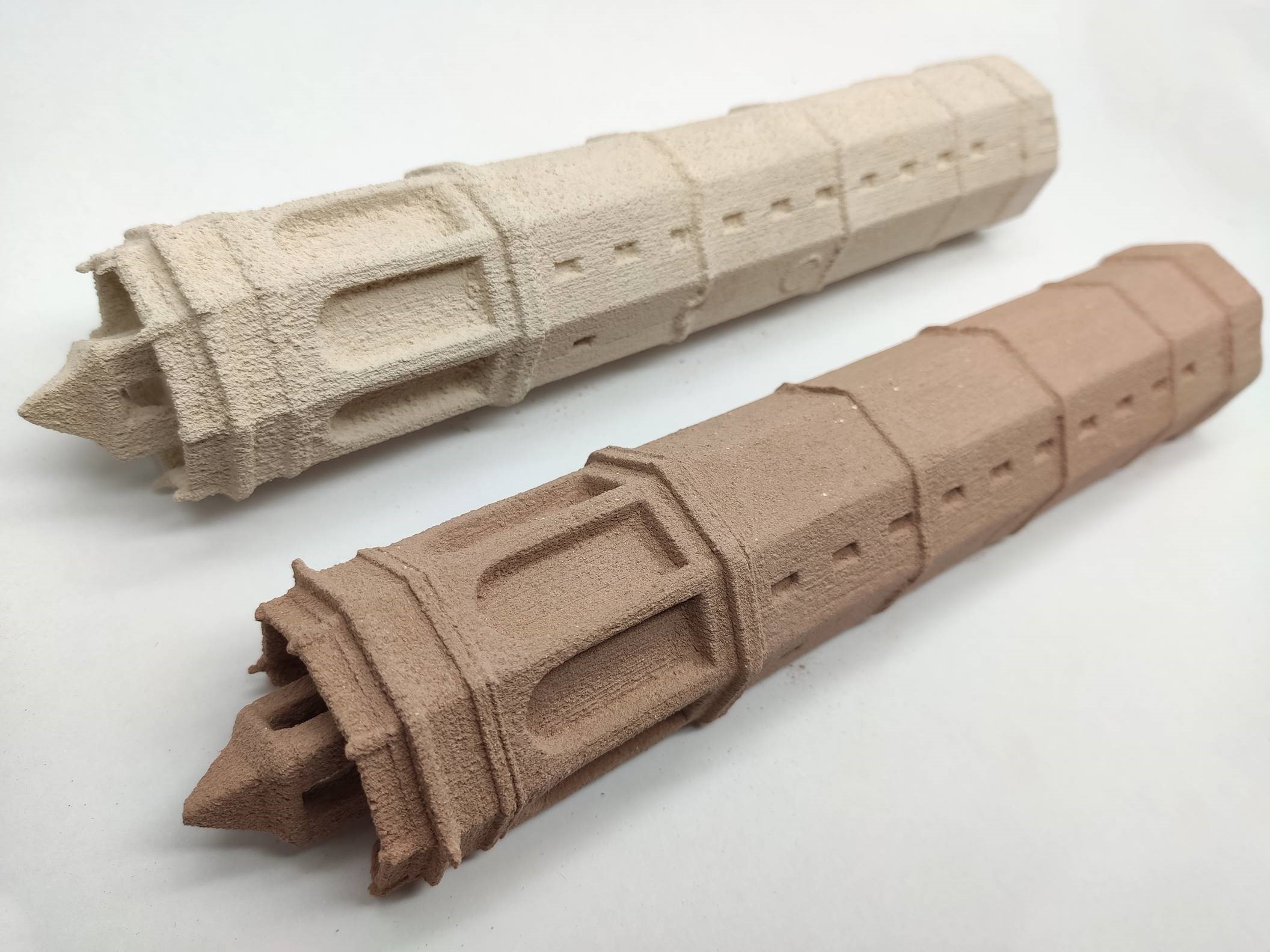

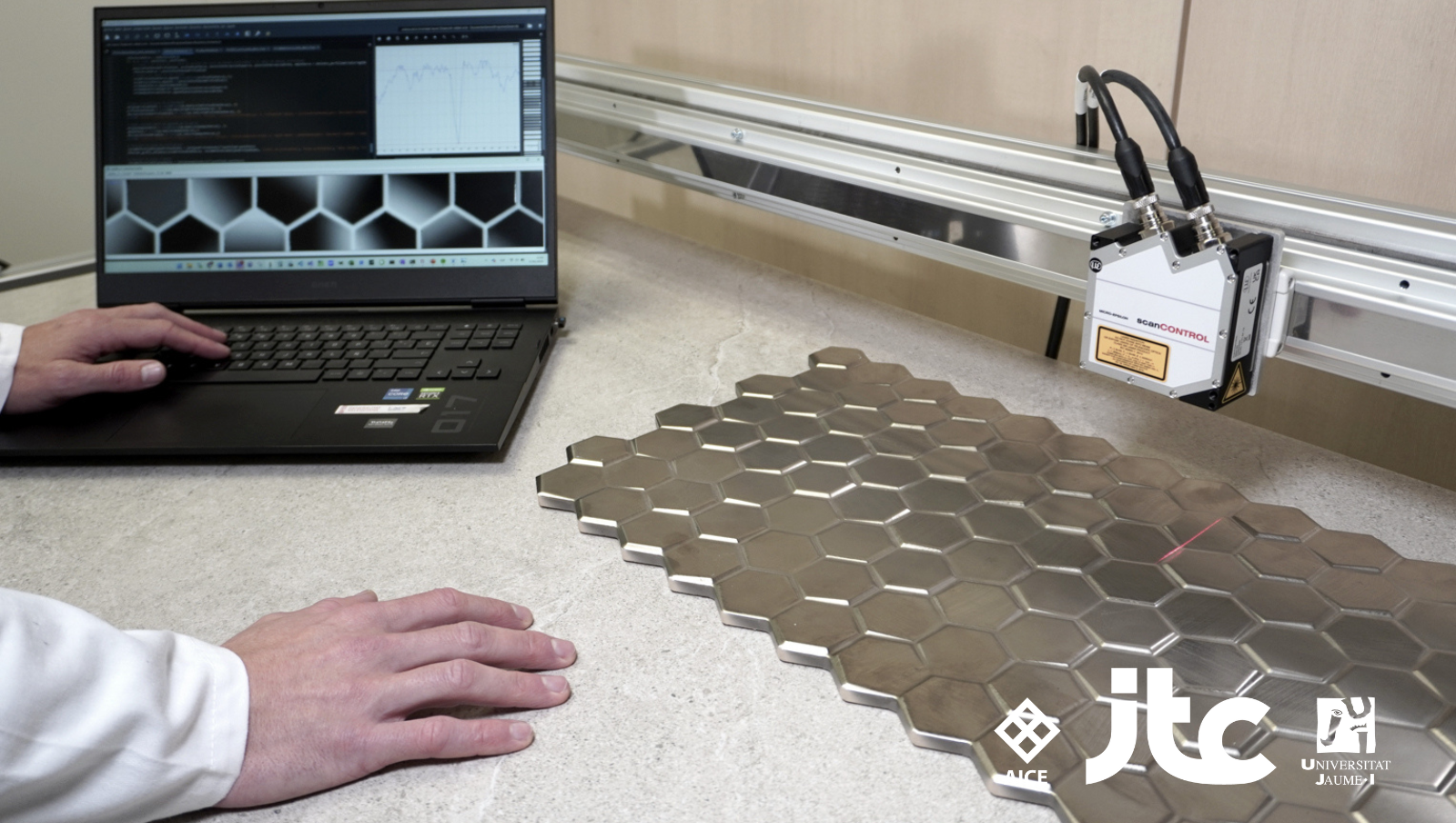

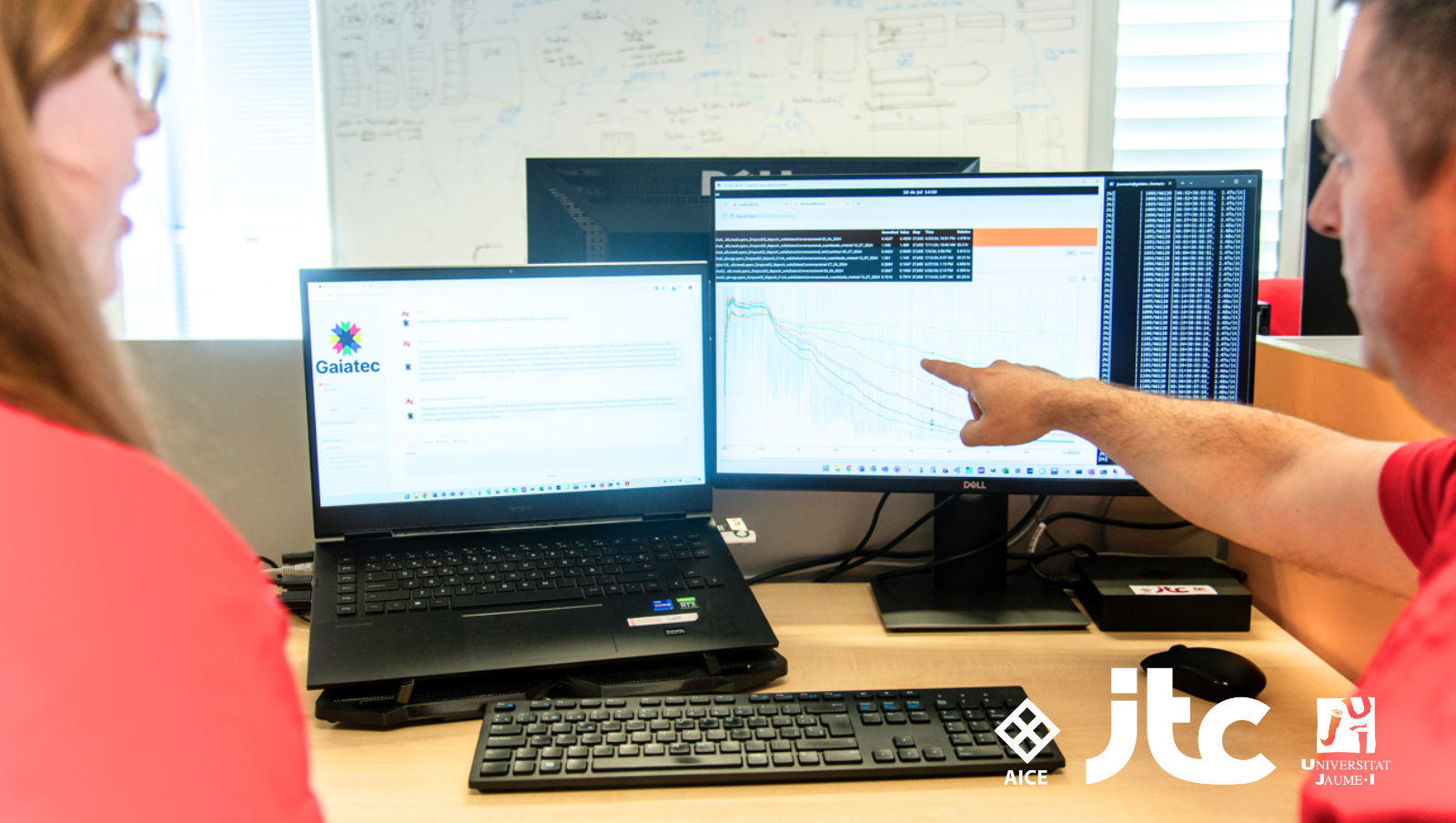

LIFE HYPOBRICK, which began in October 2019 and will end in March 2023, aims to eliminate the firing stage of the bricks manufacture, replacing it with alkaline activation technology, which uses a very low temperature and avoids 80% of emissions into the atmosphere. Specifically, these materials have been obtained from waste from the same sector and from other sectors, by means of the aforementioned alkaline activation and at a curing temperature of 80 ºC.

Los ladrillos de LIFE HYPOBRICK han sido fabricados industrialmente en la empresa Ladrillos Mora, miembro del proyecto, en Illescas (Toledo), utilizando el prototipo desarrollado también en el marco del proyecto. Este era precisamente uno de los objetivos más importantes de LIFE HYPOBRICK que se ve al fin cumplido al llevar a cabo una construcción ubicada en Illescas consistente en un muro cuyos ladrillos tienen unos 250 mm de largo por 125 mm de ancho y un espesor de 40 mm, para lo que se han utilizado alrededor de 9.000 ladrillos fabricados industrialmente en la propia empresa.

Under the coordination of the Instituto de Tecnología Cerámica (ITC-AICE), the companies Ladrillos MORA, Recycling, Consulting & Services, S.L. (RCS), the German company Schlagmann Poroton GmbH & Co. KG (SCHLAGMANN) and the Technische Hochschule Nuernberg Georg Simon Ohm (THN) are participating in LIFE HYPOBRICK.

El principal objetivo del proyecto ha sido desde el principio demostrar la viabilidad de la fabricación de productos de edificación basados en residuos (ladrillos y bloques) empleando un proceso extremadamente bajo en emisiones de CO2, para así cumplir con las guías medioambientales y del clima de la Unión Europea, reduciendo la emisión de gases de efecto invernadero en el sector industrial del 80% al 95% en el 2050. Las industrias de este tipo de productos pertenecen al grupo de industrias de energía intensiva.

The procurement and construction of this wall, whose bricks have similar properties and performance as traditional bricks, demonstrates that it is possible to help industries such as brick-making to align with the objectives set by the European Commission as well as with the Sustainable Development Goals set by the United Nations (SDGs). Specifically, LIFE HYPOBRICK is aligned with SDG 7: Affordable and Clean Energy, SDG 9: Industry, Innovation and Infrastructure, SDG 11: Sustainable Cities and Communities, and SDG 13: Climate Action.

All information about LIFE HYPOBRICK: www.lifehypobrick.eu