Castellón, 16 May 2019: On 15 and 16 May, 20 researchers in all came together at the at the Institute of Ceramic Technology (ITC) and at Keraben Grouppremises, respectively, to seek to improve ceramic manufacturing process sustainability, in particular in cleaning firing kiln emissions, through the European DREAM project, funded by the European Commission's Horizon 2020 programme, whose main aim is the development and demonstration of a series of technological innovations that can be implemented both in the latest kilns and in conventional ceramic tile firing kilns, to thus advance significantly in ceramic process sustainability.

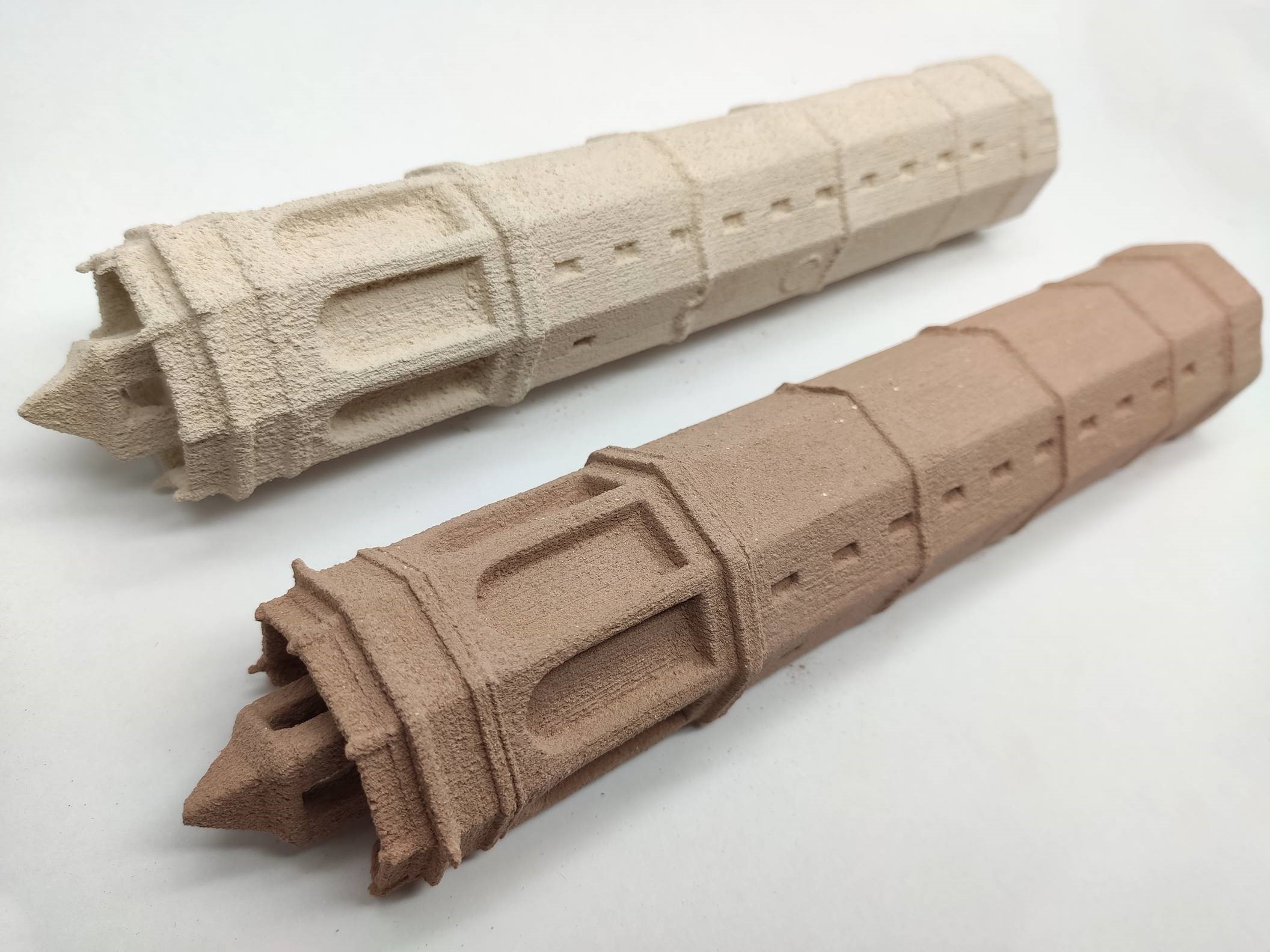

For in situ verification of these improvements, three industrial demonstrators have been developed as technological showcases for the market.

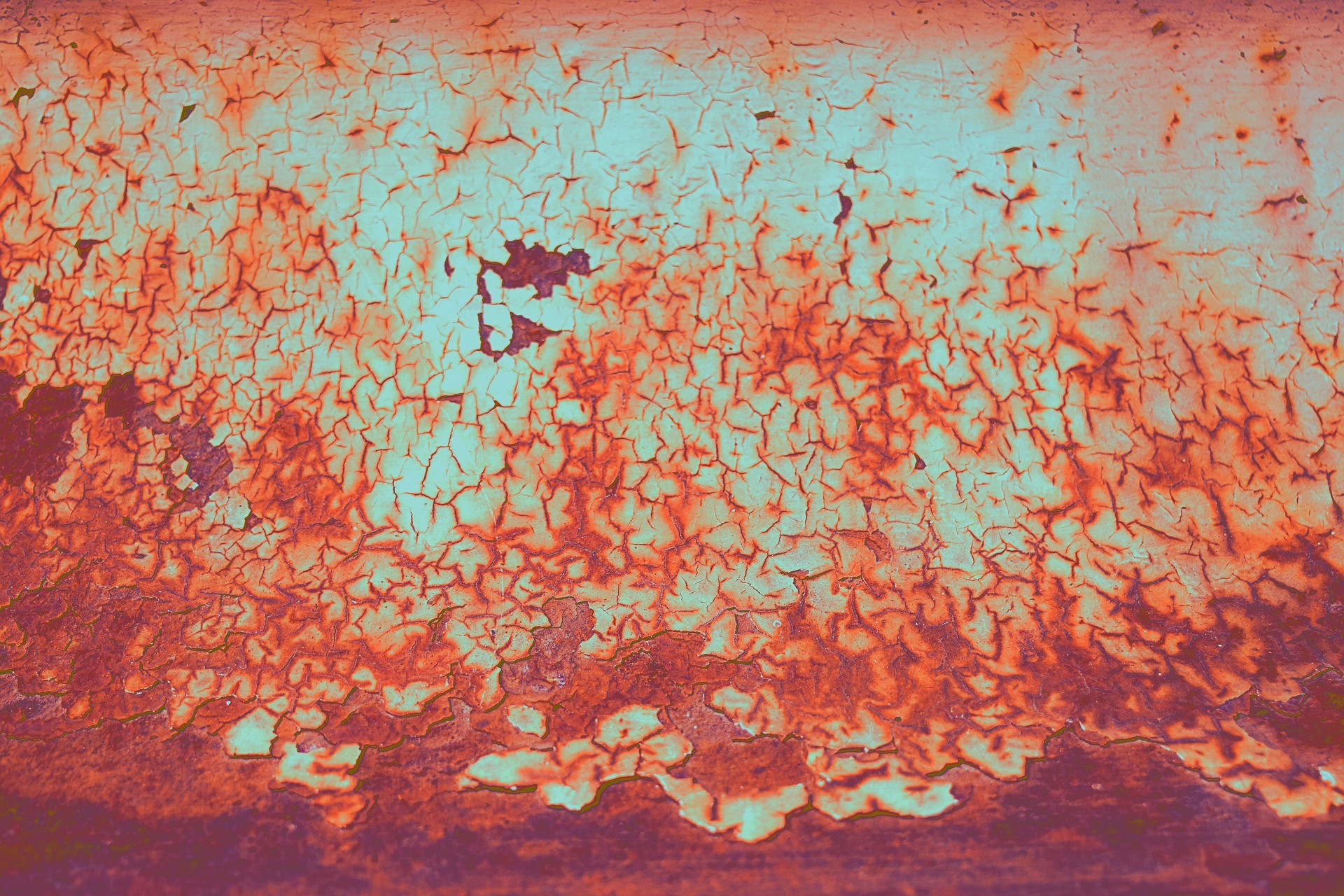

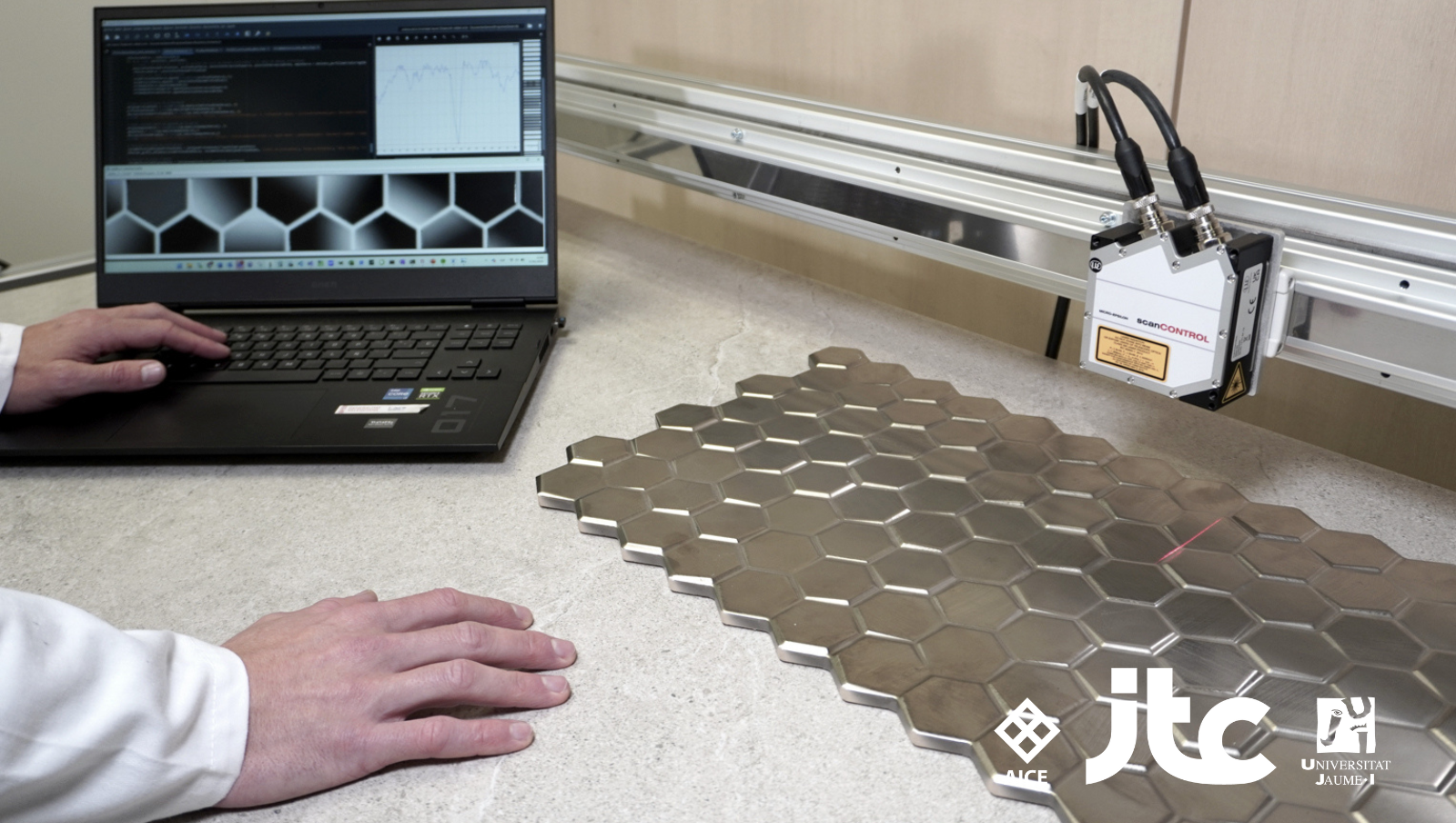

In this sense, the at the Institute of Ceramic Technology (ITC) has designed and built a pilot plant, installed at Keraben Group facilities in Nules (Castellón), consisting of a fabric filter baghouse with reagent injection and two fixed-bed reactors, in order to study acid pollutant emissions with a view to reducing these as well as other types of potentially harmful elements that are emitted into the atmosphere. Various measurement campaigns that will conclude this summer are being carried out at this pilot plant, which incorporates the latest monitoring systems for obtaining data on pollutants emitted at an industrial source in real time. This experimental study will thus allow emissions cleaning efficiency to be determined and different types of configurations to be designed.

More about the DREAM project.

DREAM, acronym for "Design for Resource and Energy efficiency in cerAMic kilns", brings together major stakeholders in the field of ceramic industry technologies and focuses on the development of innovations for application in ceramic production. The project's main aim is to reduce kiln energy consumption, pollutant emissions, and production costs, while simultaneously enhancing end-product quality.

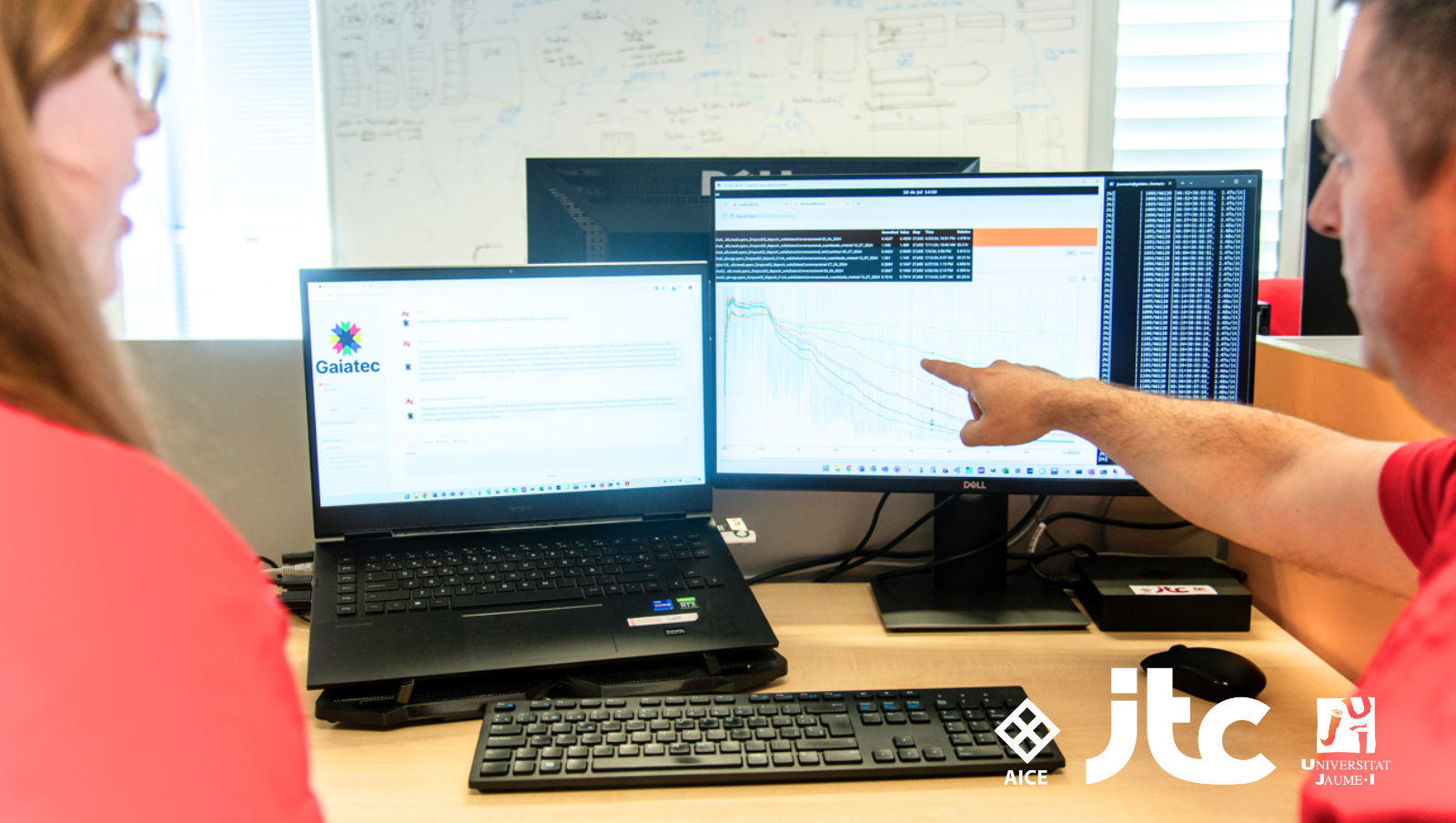

The project addresses the development of five strategic innovations for application to the new kiln: a biofuel-fed CHP unit; the study of a tool for modelling, simulation, and control of firing parameters; implementation of heat exchangers for heat control and recovery; installation of new refractory materials and linings to improve kiln insulation; and monitoring and abatement of kiln emissions.

Eleven partners are involved in the project under the leadership of ¶ Sacmi, the world's top ceramic kiln manufacturer, supported by the advisory services of CRIT, an Italian company devoted to technology innovation. Several global leaders in their respective fields complete the Dream team: Keraben Group (Spain) and Mirage(Italy), great ceramics producers; Rath(Germany) world leader in the refractories sector, supported by the co-national research institute Forschungsgemeinschaft Feuerfest. The Institute of Ceramic Technology (ITC-AICE), centre for university-business cooperation located in the Spanish ceramic network cluster and Econotherm (UK), specialists in manufacturing heat exchangers, supported by researchers from Brunel University London. There will furthermore be the valuable contribution of the Italian University of Modena and Reggio and Synesis, a company specialising in manufacturing process innovation.

More information.