Castellón, 11 de noviembre de 2019.- Gracias al proyecto: Cer-Oh ! Strategies que cuenta con la financiación del Instituto Valenciano de Competitividad Empresarial (IVACE) a través de los Fondos FEDER de Desarrollo Regional y la Línea Nominativa de la GVA. The at the Institute of Ceramic Technology (ITC) está estudiando diferentes vías para reducir emisiones de CO2 en el sector cerámico.

Concretamente, en este segundo año del proyecto, se ha desarrollado la formulación de nuevas composiciones cerámicas cuyo objetivo es reducir de forma drástica la temperatura de cocción (más de 200 º C), gracias a la presencia de materias primas fundentes que contienen en elevada proporción compuestos como fósforo y vidrios reciclados.

Otro importante avance ha sido la obtención de azulejos sin carbonatos empleando materias primas de alta fundencia, para reducir la temperatura de cocción, como, por ejemplo, vidrio reciclado y talco.

Además, se han formulado esmaltes y engobes sin utilizar frita como materia prima, para lograr diferentes acabados en la superficie de la baldosa: brillante, satinado y mate, tanto para baldosas de gres porcelánico como azulejo.

En esta línea, se está estudiando también la aplicación de estos desarrollos aplicados a la tecnología full digital con el fin de obtener acabados similares.

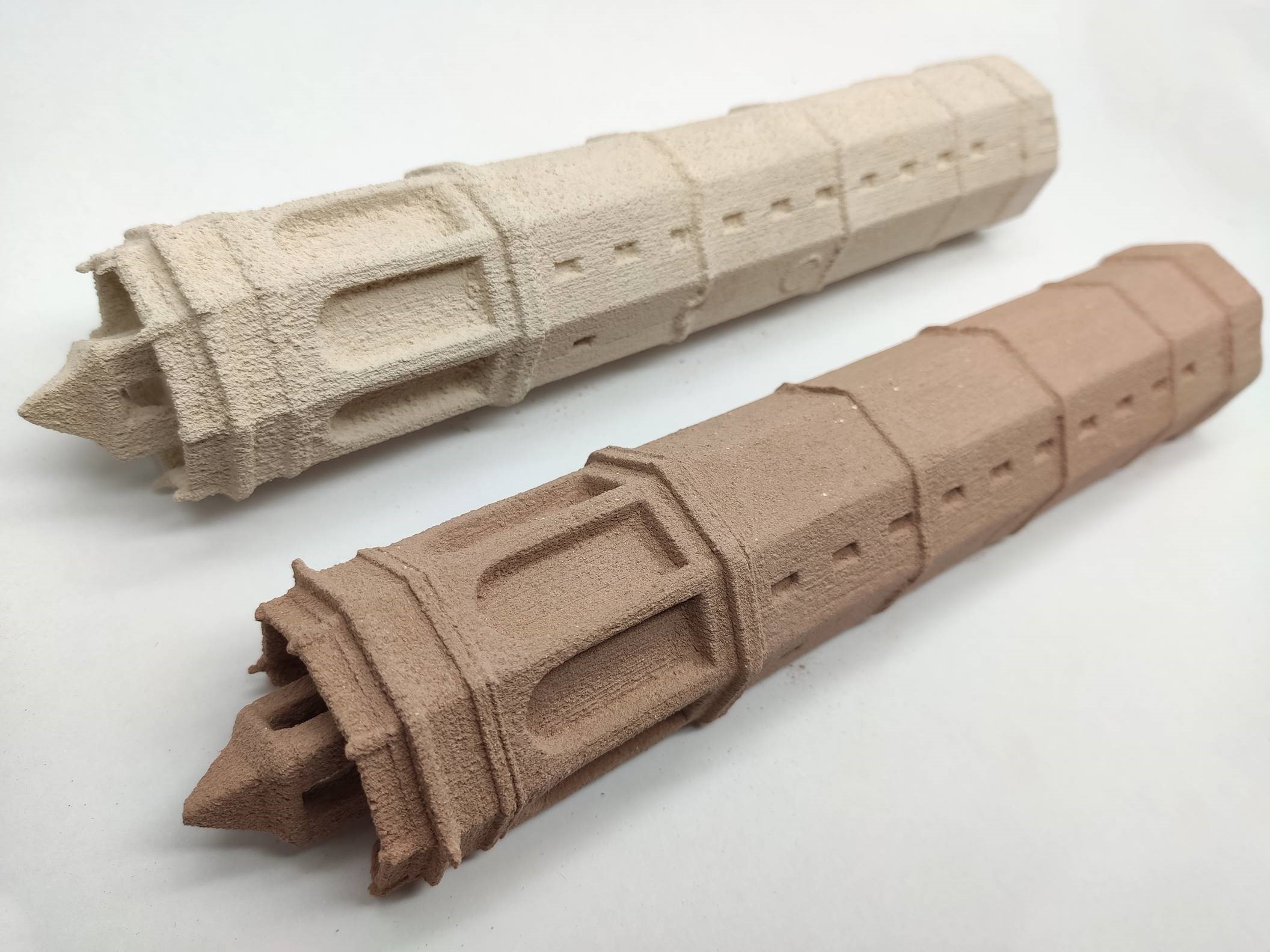

También se han desarrollado formulaciones de soportes cerámicos de alta resistencia mecánica tanto en seco como tras la cocción, para así poder reducir el espesor de las baldosas cerámicas.

Para lograr aumentar la resistencia mecánica de las mismas tras la cocción, se ha actuado tanto sobre la composición, como sobre las variables del proceso, tales como el grado de molienda o las condiciones de conformado, entre otras.

Respecto a la actividad de transición energética, se ha analizado la situación actual del sector cerámico en materia de consumos energéticos, así como el uso de las tecnologías de optimización energética que se han implantado en estos últimos años, con el fin de reducir el consumo energético en el proceso productivo.

La recopilación de esta información ha servido para establecer una línea base, con la que será posible realizar una prospectiva hacia una transición energética que comprenderá nuevos equipos productivos no basados en fuentes de energía fósil, así como la incorporación de energías renovables al proceso de fabricación.

Además, se está estudiando el consumo y la idoneidad de los procesos que no impliquen el uso de combustibles fósiles, tales como la tecnología de granulación, el secado mediante infrarrojos y métodos de cocción eléctrica, ya sea superficial como en toda la baldosa, sobre los procesos actuales en los que se utiliza gas natural.

Finalmente, se están intentando obtener baldosas “sin cocción”, desarrollando esmaltes de baja temperatura para productos activados alcalinamente y para productos silicocalcáreos.